Tiras LED COB: ¿qué son y cuándo utilizarlas?

¿Quieres resaltar un rincón de la estancia? Las tiras LED son famosas por su capacidad de enmarcar espacios y seguir formas específicas, para darles un protagonismo especial. De hecho, cuando se utilizan correctamente, pueden transformar por completo un espacio para crear efectos muy atractivos.

Sin embargo, existen algunos casos en los que las tiras LED convencionales no consiguen el efecto deseado, ya que los puntos que forman la tira pueden verse en una superficie donde se refleja, incluso aunque se utilice un difusor. Para estos casos, las tiras LED COB son una opción ideal.

¿Qué es el LED COB?

COB es la abreviatura de Chip on Board, que significa tecnología de empaquetado chip-on-board, un cuerpo emisor de luz en el que se integran múltiples chips LED COB y se empaquetan en el mismo sustrato.

La fuente de luz LED COB es una tecnología de fuente de luz de superficie integrada de alta eficiencia en la que el chip LED está conectado directamente a un sustrato de metal de espejo de alta reflectividad.

El área de emisión de luz y las dimensiones externas de la fuente de luz se pueden diseñar de acuerdo con la forma y la estructura del producto, como redonda o cuadrada.

La luz LED emitida por el chip sufre refracción, reflexión e interacción con fósforos en el gel encapsulante, y el gel emite uniformemente luz de diferentes colores de luz y temperaturas de color.

Principales ventajas y desventajas de las tiras LED COB

¿En qué casos es recomendable utilizar tiras LED COB? Al igual que las tiras LED, este formato permite tener una luz continua y una estética envolvente en el espacio donde se utiliza.

Hay ocasiones en las que queremos iluminar una superficie donde la luz se refleja. Si elegimos una tira LED convencional, veremos los puntos que se marcan en la tira. Para evitar esta irregularidad y conseguir un espacio uniforme, es recomendable utilizar tiras LED COB, en las que no se detectan estos puntos.

Otra ventaja de las tiras LED COB es que pueden reducir simultáneamente el consumo aproximadamente un 30-40%, o con el mismo consumo pueden conseguir un aporte luminoso de más del 30%.

Además, una de las principales ventajas de la luz continua es que se puede utilizar con mayor frecuencia con un difusor transparente. Las tiras LED estándar, en cambio, se suelen utilizar con difusores opalinos para evitar marcar puntos.

En resumen, estas son las principales diferencias respecto a otros tipos de luz:

- Línea continua LED.

- Suelen tener un menor consumo y mayor aporte lumínico.

- Su vida útil es más larga.

- Son más ecológicos, ya que no contienen mercurio.

- Se puede utilizar con mayor frecuencia con un difusor transparente.

Por otro lado, su principal desventaja es que al estar compuesto por más chips por metro, su coste suele ser más elevado. Depende de ti decidir si quieres conseguir un ambiente totalmente envolvente, en caso de trabajar con superficies reflectantes.

Diferentes tipos de tiras de luces COB

Las luces LED COB tienen las características básicas de las tiras de luces LED, tienen un respaldo adhesivo, se pueden cortar, se pueden conectar, tienen una larga vida útil, son seguras al tacto, son respetuosas con el medio ambiente y son fáciles de instalar.

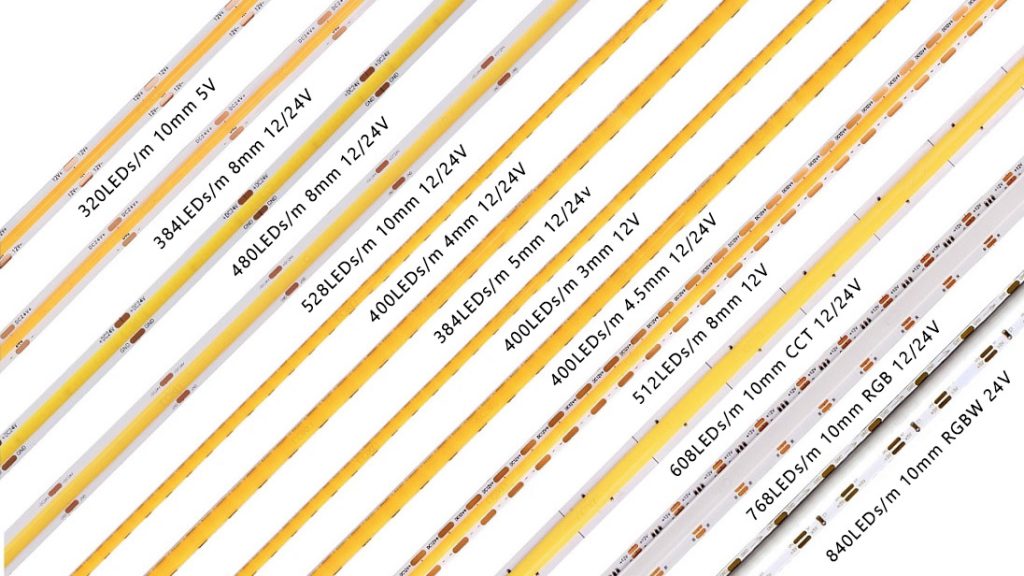

Hay muchos tipos de tiras de LED COB, diferentes voltajes, diferentes anchos, diferentes densidades, diferentes colores de luz y temperaturas de color, y todos los LED COB tienen un CRI alto.

- Voltaje: 5V / 12V / 24V

- Density(chips/m): 160, 320, 400, 384, 480, 512, 576, 840, 768, 864, 1056

- Ancho de PCB flexible: 3mm | 4mm | 5mm | 8mm | 10mm | 12mm

- Temperatura de color de la luz blanca: 2200K / 2700K / 3000K / 4000K / 6500K

- Color: Amber, White, Ice blue, Pink, Yellow, Orange, Red, Green, Marrs green, Blue, CCT, RGB, RGBW, Addressable RGB

- CRI(Ra>): 90+

¿Son mejores las luces LED COB?

Al comparar las tiras de LED COB con otras tiras de LED, podemos ver que las tiras de luz COB son, de hecho, ligeramente mejores. Y las ventajas se expresan en los siguientes aspectos.

Resistencia a la flexión, buena flexibilidad, emisión de luz de 180 grados.

Las tiras de luces LED tienen una flexibilidad limitada, ya que solo se pueden doblar para alinear las luces horizontalmente y doblarlas hacia la parte posterior de la tira.

Sin embargo, las tiras de luces LED COB se pueden enrollar, torcer y doblar. La tira COB es más flexible que las tiras de luces LED.

La superficie emisora de luz de la tira de luz COB puede alcanzar un ángulo de emisión de luz de 180°. Sin embargo, las tiras de luz LED SMD solo pueden alcanzar los 120 grados.

Ahorro de energía, alta eficiencia lumínica.

En comparación con las tiras de luces LED tradicionales, bajo la misma densidad, la potencia de las luces LED COB es mucho menor y solo representa alrededor del 50% de las tiras LED tradicionales.

Y la luz LED COB puede lograr una alta eficiencia luminosa mientras ahorra energía.

Bajo calor, buena disipación del calor.

La tira de luz COB fija directamente el chip en la PCB, lo que reduce el canal de conducción de calor, y la tecnología de alta densidad hace que la corriente en cada chip se duplique, el rendimiento de disipación de calor mejora cualitativamente y la atenuación de la luz de la tira de luz COB es menor y mayor vida útil.

Efecto de luz uniforme, suave, sin reflejos, sin puntos de luz, sin granulosidad.

Debido a las características estructurales de la luz LED COB, la superficie emisora de luz es un coloide lineal. La estructura de la tira de luz SMD es una perla de lámpara luminosa.

Por lo tanto, la luz emitida por la tira de luz COB debe ser mucho más uniforme, lineal y no hay puntos de luz.

Multicolor, regulable

Las tiras de luces LED tienen varios colores y temperaturas de color, y las tiras LED COB son iguales. Puede elegir el color y la temperatura de color que prefiera: ¿blanco cálido de 3000 K o blanco puro de 6000 K? ¿Tira LED COB de un solo color o que cambia de color RGB?

El brillo de las tiras de luces LED no siempre nos resulta agradable. Si se puede ajustar el brillo de la tira de luces, será genial configurar un brillo cómodo.

Ultrafino, alta densidad, alto CRI

Dado que el chip LED COB está conectado directamente a la placa PCB, el espesor de la PCB es ultrafino. Si desea ocultar la tira de LED, la iluminación de tira ultrafina es una buena opción.

La tira de luz LED COB de alta densidad logra una linealidad perfecta de punto a línea y superficie, lo que está más en línea con el concepto de diseño del diseñador actual de no ver la luz, y el campo de aplicación será más amplio.

Un CRI alto significa que la fuente de luz puede restaurar más colores a los objetos. Las tiras de luces LED COB con un CRI alto hacen que sus sentidos sean más intensos y le resulte más fácil distinguir los diferentes colores.

Una buena tira de luz LED no puede prescindir de una buena reproducción cromática. Puedes imaginar que estás en un jardín y que hay muchas flores hermosas. Con un CRI alto, puedes ver la belleza del jardín y sentirás una variedad de colores brillantes.

Pero con un CRI bajo, todo lo que verás será en escala de grises, como una película en blanco y negro. Y lo único que indica es que es necesario un CRI alto.

¿Cómo cortar tiras de led COB?

Para cortar la tira COB, solo necesitas unas tijeras. Por supuesto, utiliza una regla para medir la longitud que necesitas antes de cortarla.

La placa PCB de la tira de luz tiene claramente marcados los lugares que se pueden cortar, y se puede cortar a lo largo de estas líneas. La longitud unitaria de la línea de corte de la tira de luz LED es diferente, lo que está determinado por el diseño del circuito dentro de la PCB (placa de circuito impreso).

Las unidades pequeñas antes de cada grupo de líneas de corte están conectadas en paralelo, por lo que aún se pueden utilizar normalmente después del corte.

Para obtener instrucciones específicas sobre el corte y la instalación, puede consultar otro artículo del blog de iluminación LED de YIFORD.

Aquí encontrará una explicación detallada de cómo instalar la tira de luz COB, 8 pasos, paso a paso:

- Prepare la tira de luz LED/fuente de alimentación/controlador y las herramientas relacionadas.

- medir la longitud requerida

- Cortar las tiras de LED según sea necesario

- Cómo conectar rápidamente el cable de alimentación

- Pruebe la tira antes de la instalación

- Cómo pegar la tira de iluminación en la posición deseada

- Conecte la fuente de alimentación del LED y el controlador LED o el atenuador LED

- Prueba por última vez y ajústalo a tu color favorito.

Cómo instalar tiras de luces LED COB en tus proyectos

Cortar en la marca designada, las tiras de led se pueden usar normalmente, ¿qué pasará si no se corta en la marca designada?

Por ejemplo, te darás cuenta de que varias luces al final no están encendidas.

La forma de solucionar este problema es cortar el resto de las luces inciertas, recuerda cortar por la línea de corte.

Las longitudes de la unidad de corte de algunas tiras COB

Tiras de luces LED COB de 12 V y 24 V, longitud de corte

Es posible que haya descubierto que, en general, la longitud de corte de 12 V y 24 V es la misma, como las tiras de luces LED COB blancas y las tiras de luces LED de un solo color. pero para las tiras de luz COB sintonizables, las tiras de luces LED direccionables RGB, las tiras de luces LED COB de 12 V, las tiras de luces LED COB de 24 V, cada longitud de corte es diferente, esto se debe a que el diseño de la PCB es diferente, la longitud que se puede cortar es la misma que está determinada por la densidad de las lámparas del conjunto de chips, la cantidad de perlas de lámpara distribuidas en cada segmento y la configuración actual.

¿Pueden las luces LED COB utilizar canales de aluminio?

La función de los canales de aluminio para LED es proteger las tiras de luces LED y emitir un mejor efecto de luz. Si no desea ver la tira de luces LED al descubierto, puede instalar un canal de aluminio para ocultar la tira de luz. El uso de canales de aluminio también puede hacer que el efecto de instalación sea más hermoso.

El uso de canales de luz para luces LED COB puede resolver los defectos visuales de las partículas reflectantes. Ya sea una oficina, una tienda comercial o un espacio de ocio, el estilo de iluminación lineal puede aportar puntos visuales adicionales al espacio al proporcionar iluminación.

Si necesitas ayuda o tienes dudas sobre la tira de luz led contacta con nosotros.